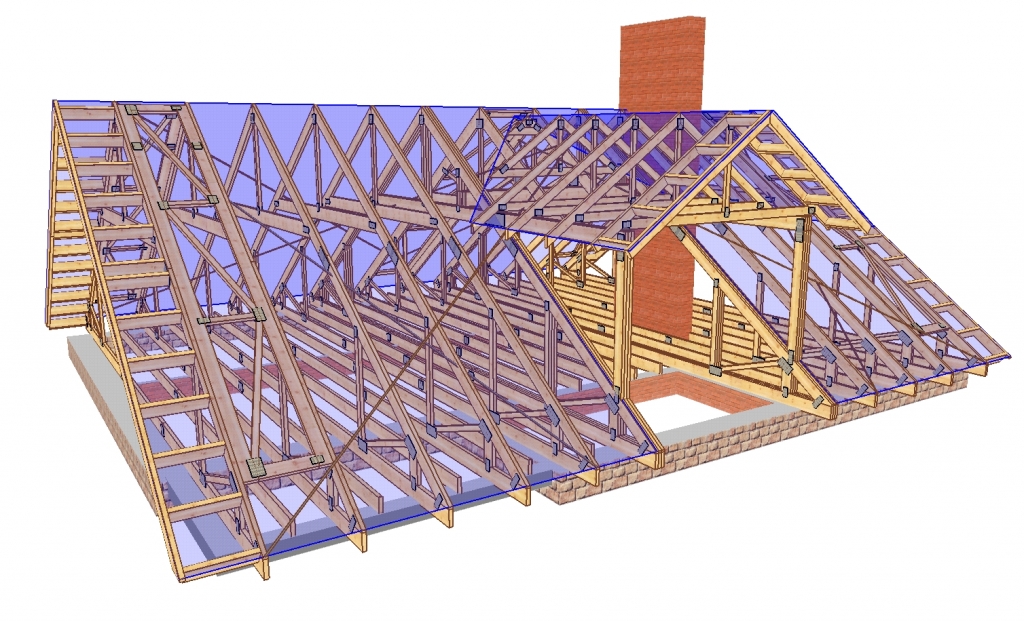

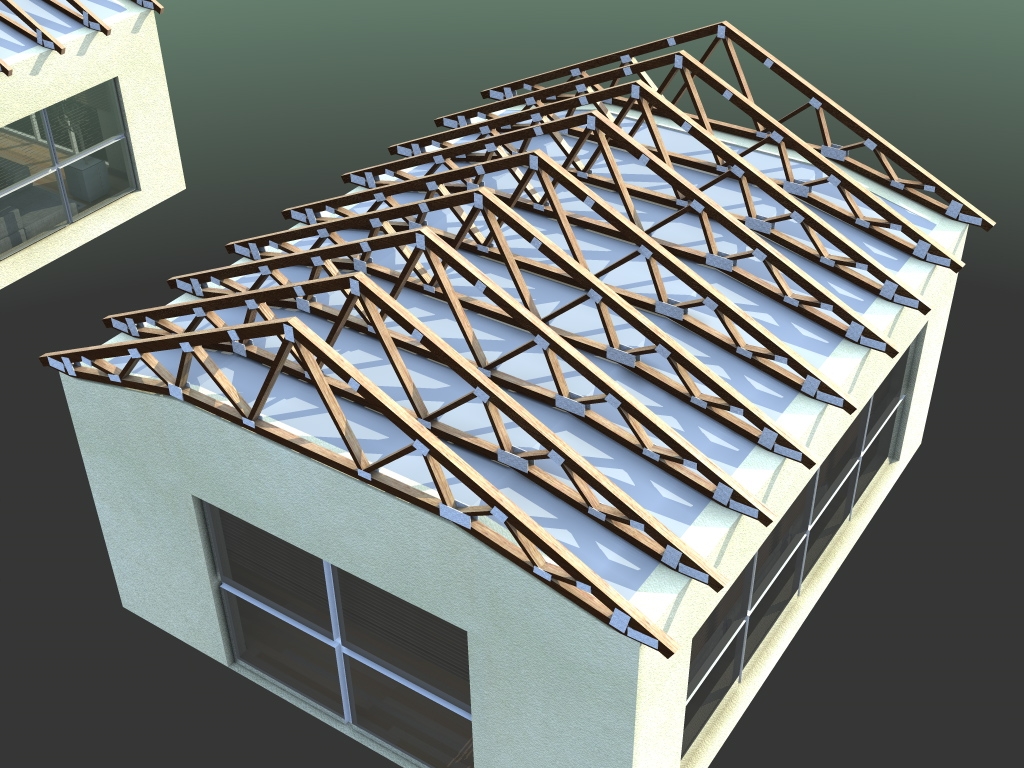

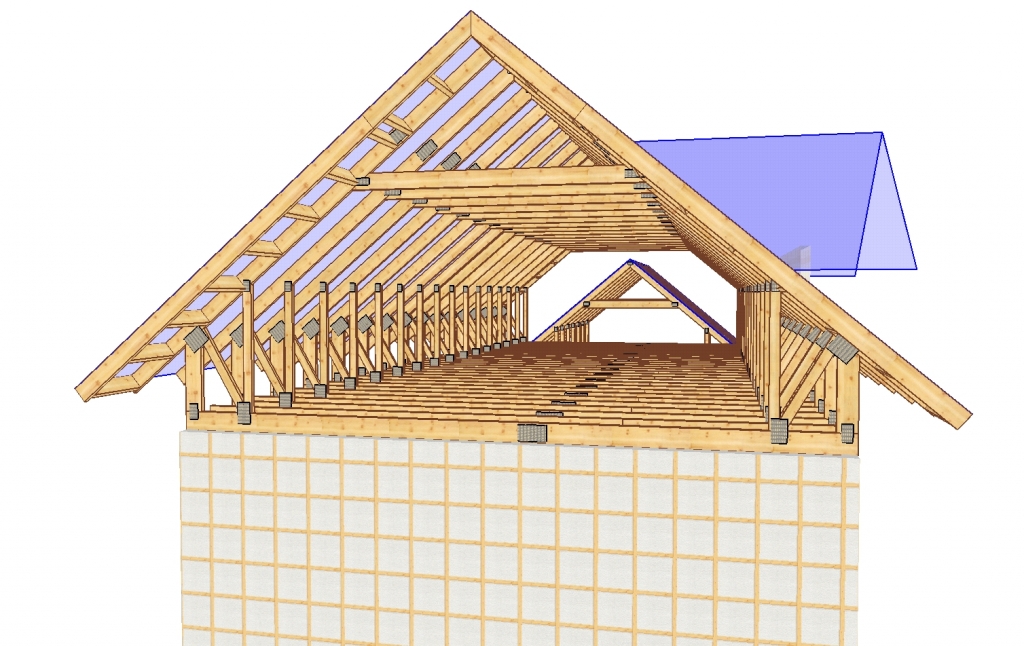

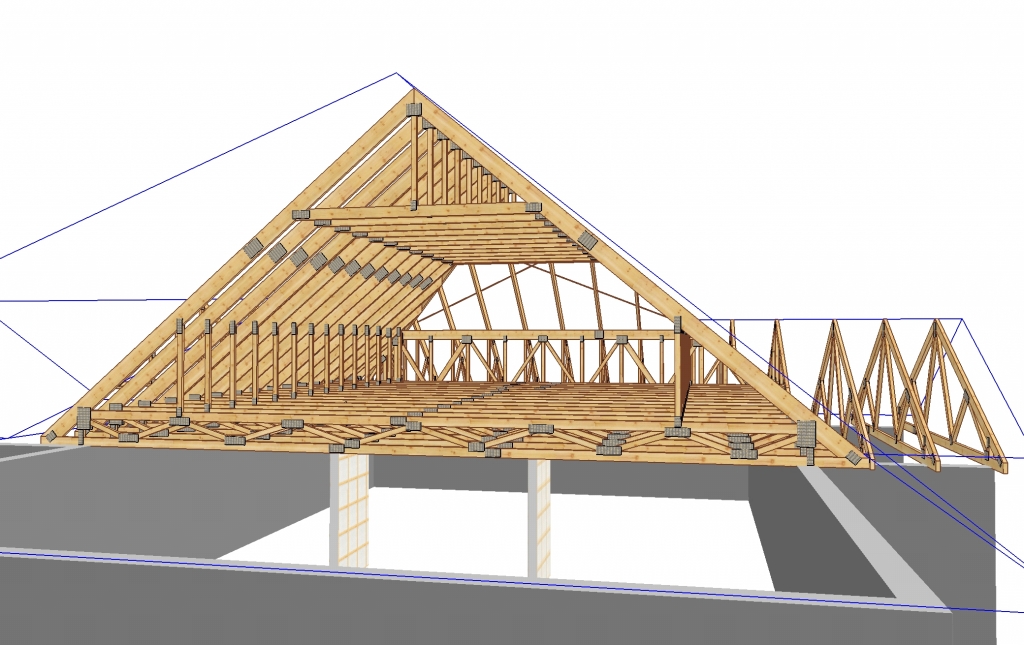

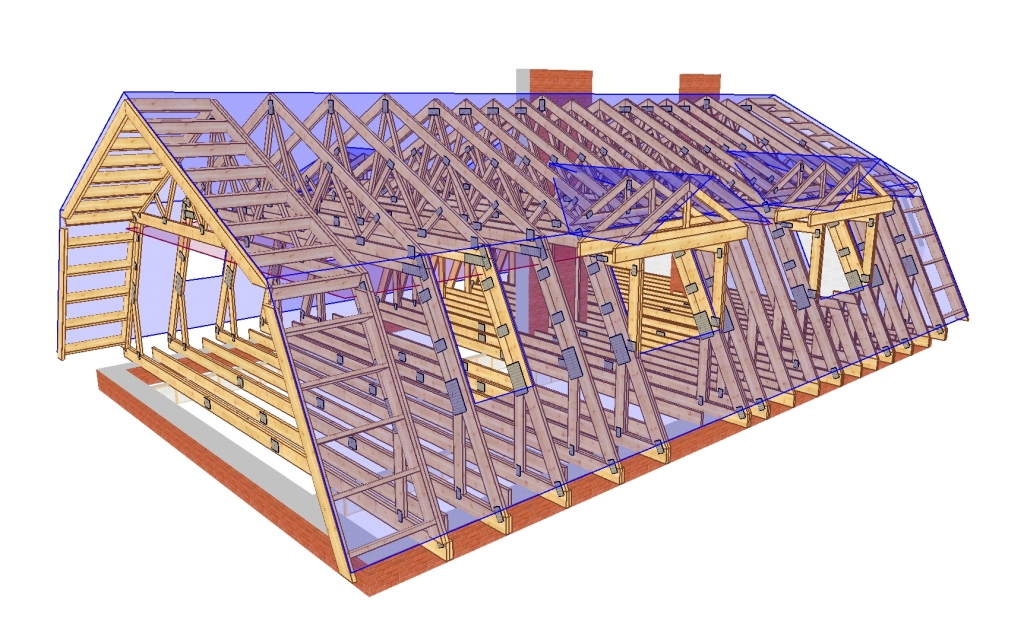

Trusses

Prefabrication of timber roofs with the use of Mitek nail plates:

- gives a new dimension to the construction of timber roofs,

- gives a possibility to adjust the chosen solution to the shape of the roof and the investment costs,

- enables to design internal walls in various ways without the need to pour foundations underneath them,

- gives a possibility to accommodate a large attic without the use of supporting pillars,

- makes the assembly of electrical installations, parts of ventilation and insulation systems or others a very easy task.

Implementation of our solutions = safety for you and your family and friends / Feel safe at your own house

Planning the expenses is a crucial part of every investment. See how we make your money stay in your pocket:

The prefabrication of timber structures with the use of truss technology guarantees that the materials are tailored-made and the quality will last for years....Read more